TTI maintains a strong focus on advancing cordless technology and delivering innovative product solutions across key markets. Our diverse portfolio features renowned brands such as MILWAUKEE, RYOBI, and HOOVER, recognized as market leaders on a global scale.

With a commitment to excellence, our products have received international acclaim from numerous third-party organizations, reflecting our dedication to pioneering design and innovation. These accolades underscore our commitment to pushing boundaries and affirm our capability to consistently deliver products at the forefront of the industry.

TTI is proud to announce that we have received over 50 product-related awards across our brands from various organizations during the reporting period.

Petrol to DC

-

Pro Tool Innovation Award – Rammers

WINNER

-

Pro Tool Innovation Award – Battery‑Powered Jobsite Generators

WINNER

WHISPER Series

24” Two-Stage Snow Blower

-

Pro Tool Innovation Award – Battery Powered Snow Blowers

WINNER

-

International Design Excellence Awards – Finalist

Ergonomic and Safety

-

Pro Tool Innovation Award – Battery Accessories

WINNER

1” Railway High Torque Impact Wrench

-

Design for Asia Awards – Bronze

-

Australian Good Design Awards

WINNER

Noise Reduction

-

Pro Tool Innovation Award – Fans

WINNER

Brushless Centrifugal Blower

-

Green Good Design WINNER

Energy Efficiency

Tower Light

-

Pro Tool Innovation Award – Commercial Site Lighting

WINNER

Tripod

LED Light

-

Pro Tool Innovation Award – Portable Work Lights WINNER

Modilarity

-

Pro Tool Innovation Award – Battery‑Powered Multi‑head

WINNER

-

International Design Excellence Awards – Silver

Design Efficiency

Brushless

Crushing

Shredder

-

Design for Asia Awards – Silver

Bucket Top

Wet/Dry

Vacuum

-

Pro Tool Innovation Award – Shop Vacuum

WINNER

In today’s rapidly evolving world, the demand for more sustainable and efficient solutions has never been greater. MILWAUKEE has been at the forefront of this movement, leading innovation in battery-powered tool technology for nearly two decades. Our advanced outdoor power equipment and the groundbreaking MX FUEL Light Equipment System are engineered to deliver the power of traditional gas equipment while helping users work safer and more productively.

Gas-powered equipment has long been associated with significant drawbacks. Emissions from gas engines not only pollute the environment, but also pose health risks for users and those nearby. Starting these engines can be a frustrating and time-consuming process, often requiring multiple pull start attempts. Noise from gas engines disrupts both neighborhoods and work sites, creating an unpleasant experience for everyone. Maintenance demands are high, with frequent servicing needed to keep engines running optimally. Plus, there’s the added hassle of mixing gas and oil - another layer of complexity to these tools.

MILWAUKEE’s battery-powered outdoor equipment and MX FUEL System provide the solution. By eliminating emissions, our equipment contributes to a cleaner, healthier environment. With a simple push of a button, the hassle and fatigue of pull starts is gone. Noise levels are reduced for quieter operation and minimal disruption. Maintenance is simplified, with fewer moving parts, no carburetor maintenance, and reduced use of non-recyclable oil filters, air filters, and spark plugs. Without the need to mix gas and oil, our tools are easier and more convenient than ever.

At MILWAUKEE, we’re focused on solving the safety and productivity challenges our users face every day. By ensuring full compatibility across our systems, we empower our users with tools and equipment that work seamlessly together, providing a powerful, comprehensive solution that meets their diverse needs—today and into the future.

No pull starts

Battery-powered Outdoor Power Equipment (OPE) starts instantly and reliably, eliminating the need for a traditional pull start. This feature improves productivity and reduces operator fatigue, enabling landscape professionals to work efficiently with less physical strain.

No engine maintenance

With no engine maintenance required, battery-powered OPE reduces downtime and operational costs. Landscape professionals can stay focused on their tasks without the disruptions of servicing gas engines.

Low noise

Operating with significantly reduced noise, battery-powered OPE allows for clear on-site communication and minimizes disturbances. This quieter functionality makes it ideal for use in residential or noise-sensitive areas, helping professionals adhere to noise restrictions.

No CO2 or exhaust emissions*

Battery-powered OPE produces no CO2 or exhaust emissions while in use, ensuring no harmful exhaust affects the operator or the environment. This makes it an eco-friendly choice for landscaping professionals committed to sustainability.

No mixing gas and oil

Battery power eliminates the need to mix gas and oil, reducing the risks of incorrect fuel ratios and eliminating fuel storage requirements. This simplifies operation and minimizes potential hazards, enhancing safety.

We built our company on being responsible stewards of people’s landscapes, while also being responsible for our people, who maintain the landscapes. The move to battery power allows us to continue doing both.

Owner of a California-based landscape design, construction and maintenance company

No pull starts

MX FUEL provides instant, reliable startup without a traditional pull start, allowing users to begin work immediately. This feature reduces operator fatigue and eliminates delays commonly associated with gas-powered equipment.

No engine maintenance

Powered by a POWERSTATE brushless electric motor, MX FUEL requires minimal maintenance due to its limited wearable parts. This reduction in maintenance needs decreases downtime and lowers operational costs, enhancing productivity.

Low noise

MX FUEL operates at much lower noise levels, facilitating on-site communication and reducing disturbances. This quiet operation is particularly advantageous for projects in residential areas or at times when noise restrictions are in place.

No CO2 or exhaust emissions*

With no CO2 or exhaust emissions while in use, MX FUEL products allow for safe operation in enclosed or restricted spaces where gas-powered equipment could pose health risks, contributing to a healthier work environment.

No mixing gas and oil

MX FUEL’s battery-powered system eliminates the need to mix gas and oil, minimizing fuel handling risks and enhancing job site safety. This streamlined operation reduces storage and transportation concerns, allowing workers to focus fully on the task at hand.

*When product is in use

The efficiency, reliability, and durability of these solutions have opened our eyes to how much safer and more productive we’ve become on the jobsite.

Field Laborer for a leading heavy construction contracting company based in New York City

BUILT FOR PRODUCTIVITY

MILWAUKEE is a world leader in jobsite solutions and has been enhancing user safety through product innovation for over 100 years. From the early stages of research, design, and development, safety remains a core focus of MILWAUKEE’s approach. By creating and implementing our 7 Pillars of Safety, MILWAUKEE invests the time to work closely with users, gaining a deep understanding of the evolving workplace demands and delivering comprehensive solutions for safer, more productive jobsites.

1. Safety Technology

MILWAUKEE is dedicated to designing innovative power tool and equipment solutions that enhance user safety through groundbreaking advancements in battery, motor, and electronic technologies. From industry-first features like AUTOSTOP control, which halts a tool during a bind-up, to RAPIDSTOP brake, which quickly stops tool operation, MILWAUKEE is setting the standard for safer jobsite tools.

For high-risk tasks like cutting potentially live cables, the new M18 FORCELOGIC 5” Underground Cable Cutter with Wireless Remote sets a new benchmark for intelligent cutting solutions. Utilizing bluetooth technology, users can activate cuts remotely, keeping themselves safely separated from hazardous areas and significantly reducing jobsite risks.

2. Ergonomics

To combat musculoskeletal disorders, MILWAUKEE is committed to making ergonomics a key aspect of our product development process. Our evidence-based approach improves traditional workflows and delivers innovative solutions like the M18 FUEL Overhead Rotary Hammer with Integrated Dust Extraction. This solution’s 2-in-1 design delivers improved ergonomics for overhead work compared to traditional rotary hammer and dust extractor attachments, while meeting OSHA Table 1 requirements. This SDS Plus rotary hammer provides several new features that keep operators productive and comfortable for repetitive drilling overhead. The built-in dust extractor creates a compact, lightweight tool with optimized balance for less fatigue. The newly designed side handle, now located near the rear handle, allows the operator to maintain better body posture throughout the application.

3. Vibration & Noise

Hand-arm vibration syndrome and noise-induced hearing loss remain significant concerns for tradespeople across jobsites due to repeated exposure. At MILWAUKEE, we are dedicated to providing solutions that reduce noise and vibration exposure. For example, the M18 FUEL 16” String Trimmer delivers significantly less vibration than gas-powered alternatives—2.2 m/s² compared to gas at 8.4 m/s². This reduction minimizes hand and arm fatigue, enhances operator comfort during extended use, and improves precision and control.

4. Visibility

MILWAUKEE site lighting is the industry’s first system of high-output LED lights designed to deliver full-day runtime in portable packages. Using advanced lighting technology, these lights provide a consistent beam, optimized color temperature, and accurate color representation, creating a more productive work environment. Built to shine brighter, last longer, and withstand the demands of professional use, our jobsite lights adapt, perform, and endure. For example, the M18 ROVER Dual Power Triple-Panel Flood & Area Light delivers 4,500 lumens of high-performing flood and area lighting. Its three folding panels ensure optimal coverage, with multiple brightness modes and individual light head power options to meet any jobsite lighting need.

5. Emissions

Gas equipment remains a common presence on today’s jobsites, increasing the risk of respiratory diseases from exposure to gas fumes and emissions. At MILWAUKEE, we are dedicated to delivering battery-powered solutions through our M18 and MX FUEL systems, eliminating the hazards associated with gas equipment. For example, the MX FUEL 70kg Rammer produces no CO2 or exhaust emissions*, creating a safer work environment indoors and in confined spaces like trenches. It also features fewer wearable parts, reduced noise, and lower vibration. With a push-button start and no engine maintenance required, users experience less downtime, enabling them to complete jobs faster.

*While in use

6. Dust Management

Our MILWAUKEE business is committed to providing safe, versatile silica dust management solutions that help users comply with the Occupational Health & Safety Administration’s (OSHA’s) silica standard. Designed to enhance productivity, our solutions include the new M18 FUEL PACKOUT 9 Gallon Dual-Battery Dust Extractor w/ VACLINK, which simplifies dust compliance. Its Automatic Filter Cleaning mechanism delivers the highest sustained airflow to maintain productivity during dust extraction applications, while the inclusion of two HEPA filters ensures compliance with OSHA Table 1 requirements.

7. Personal Safety

We are committed to keeping users safe and productive on the jobsite. For years, personal protective equipment (PPE) has seen little innovation, often leading users to modify their gear to meet their needs. By understanding these challenges, we’ve developed PPE from the ground up, including head protection that adapts to any job. The new BOLT Safety Helmet with IMPACT ARMOR Liner offers advanced protection against slips, trips, and falls. As part of the BOLT System, these helmets allow users to secure multiple accessories simultaneously, enhancing productivity without compromising safety. At MILWAUKEE, we focus on creating innovative PPE solutions that keep users safe and productive.

RYOBI continues to lead the way in cordless cleaning innovation with a suite of cordless cleaning products encompassing the USB Lithium, 18V ONE+ and 40V platforms. These innovative solutions offer all users innovative cordless options to replace both corded and alkaline-powered solutions with rechargeable lithium-ion power, ranging from stick vacuums, hand vacuums, and wet/dry vacuums to scrubbers and spot cleaners.

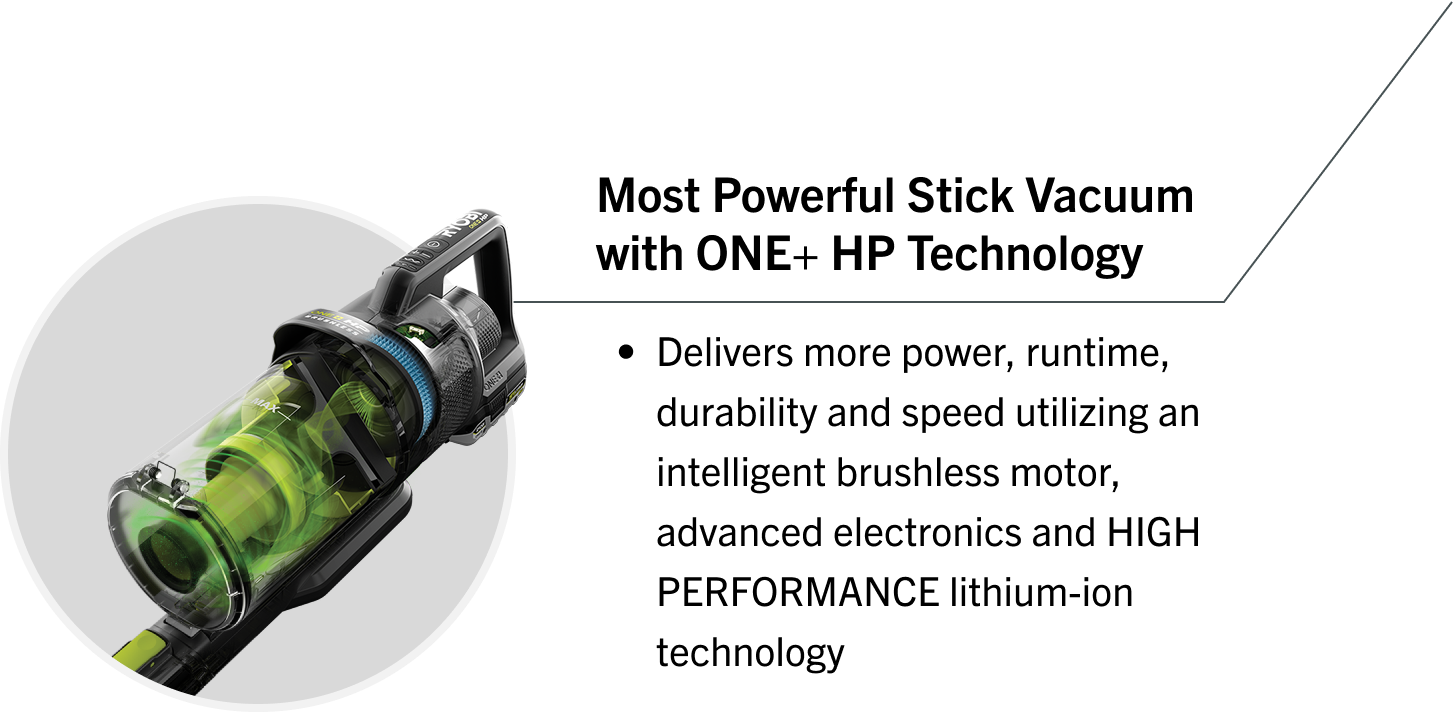

In 2024, RYOBI introduced its most capable cordless stick vacuum to date, the 18V ONE+ HP Advanced Stick Vacuum. Equipped with WHISPER Series technology, this stick vacuum provides best in class sound at only 61 dB. Its HEPA filter captures up to 99.97% of particles. This vacuum offers 12 different cleaning configurations to tackle any job, which means fewer cleaning tools taking up space in your home. This powerful vacuum makes it easy for users to handle any mess with its intelligent brushless motor, advanced electronics, and HIGH PERFORMANCE lithium-ion battery technology.

The USB Lithium platform includes innovative cleaning products that offer an alternative to disposable alkaline batteries, reducing waste and providing a convenient rechargeable option.

STICK VACUUM

Cofigurations

Rate by HEPA Filter

Most Powerful Stick Vacuum with ONE+ HP Technology

- Delivers more power, runtime, durability and speed utilizing an intelligent brushless motor, advanced electronics and HIGH PERFORMANCE lithium-ion technology

Pet Rated with Wrap Defense Roller Bar

- Minimizes hair wrap up to 9” long

- Tool free removal

HEPA Filter

- Captures up to 99.97% of particles down to 0.3 microns such as dust, pollen and pet dander